molybdenum -lanthanum alloy plate

W Content: 50% (wt%)

Mo Content: 50% (wt%)

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Molybdenum-Lanthanum Alloy Plate Product Introduction

Molybdenum-Lanthanum (Mo-La) alloy plate is a high-performance material widely used in industries that require excellent strength, high-temperature resistance, and stability. Its primary component, molybdenum, is combined with lanthanum oxide, which enhances the material’s grain structure, providing superior resistance to recrystallization, making it ideal for high-temperature applications such as in the aerospace and electronics industries. Shaanxi Peakrise Metal Co., Ltd. is a trusted supplier of high-quality Molybdenum-Lanthanum alloy plates. With years of experience in producing and exporting refractory metals, we focus on providing reliable and long-lasting solutions for industries that demand premium performance.

At Shaanxi Peakrise Metal Co., Ltd., we prioritize quality, ensuring that our Mo-La alloy plates meet international standards. Our product line is designed to meet the requirements of clients who need reliable materials for high-stress environments, making them suitable for applications like furnace components, structural elements in high-temperature environments, and electronic shielding. We continuously refine our production processes to deliver the best quality products that our customers trust for durability and high performance.

Product Parameters Table

| Product Name | molybdenum -lanthanum alloy plate | |||||||||

| Tensile strength | 610 Mpa | |||||||||

| Elongation | ≥10% | |||||||||

| Material Composition | Mo1,TZM,Mo-La | |||||||||

| Purity | ≥99.95% | |||||||||

| Use temperature | 1800°C | |||||||||

| Highest temperature | 2200°C | |||||||||

| Grade | Main element% | Impurity components(less than%) | |||||||||

| Mo | Ti | Zr | C | La2O3 | C | 0 | N | Fe | Ni | Si | |

| Mo1 | Remian | — | — | — | — | 0.01 | 0.007 | 0.002 | 0.01 | 0.002 | 0.01 |

| TZM | Remian | 0.40~0.55 | 0.06~0.12 | 0.01~0.04 | — | — | 0.03 | 0.002 | 0.01 | 0.005 | 0.005 |

| MoLa | Remian | — | — | — | 0.4~0.7 | 0.01 | — | 0.002 | 0.01 | 0.002 | 0.01 |

Product Functions

-

High-Temperature Stability

Molybdenum-Lanthanum alloy plates exhibit outstanding performance in extreme temperature environments. The addition of lanthanum enhances the material’s resistance to recrystallization, maintaining its structural integrity and mechanical properties even at temperatures exceeding 1500°C. -

Enhanced Ductility

The presence of lanthanum improves the ductility of molybdenum, making Mo-La alloy plates easier to machine and shape. This property is critical for applications that require precise dimensions and high mechanical strength. -

Superior Corrosion Resistance

Mo-La plates are resistant to oxidation and corrosion, especially in harsh chemical environments. This characteristic ensures longevity and reliability in industries such as chemical processing and furnace construction. -

Thermal Conductivity

With excellent thermal conductivity, Mo-La alloy plates are suitable for heat transfer applications, making them ideal for use in heat exchangers, electronic components, and thermal shields.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

-

Aerospace Industry

Mo-La alloy plates are widely used in aerospace components where materials must endure high temperatures and stresses. They are utilized in turbine engines, heat shields, and propulsion systems, offering durability and reliability under extreme conditions. -

Furnace Construction

Due to their high melting point and resistance to recrystallization, Mo-La alloy plates are perfect for furnace components such as heating elements, support structures, and shielding in both vacuum and hydrogen furnaces. -

Electronics and Semiconductors

In the electronics industry, Mo-La alloy plates are used as substrates and shielding materials. Their high thermal conductivity and stability make them ideal for heat dissipation in electronic devices, extending the lifespan of critical components. -

Medical Devices

The excellent corrosion resistance of Mo-La alloy plates makes them suitable for use in medical devices, especially those exposed to harsh sterilization environments.

|

|

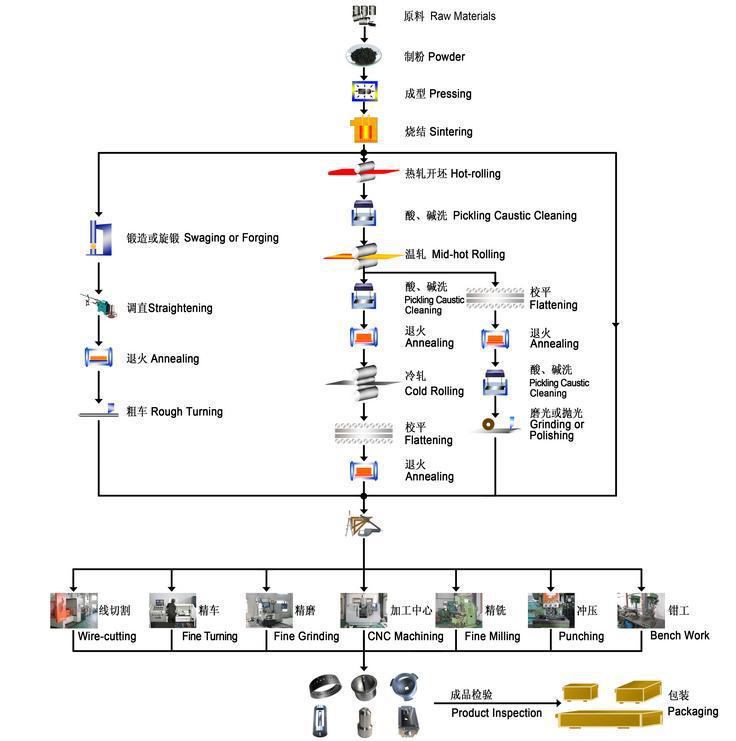

Product Process and Production Flow

The production process of molybdenum-lanthanum alloy plates at Shaanxi Peakrise Metal Co., Ltd. starts with the selection of high-purity raw materials, followed by powder metallurgy techniques such as sintering and forging. These processes ensure the highest density and uniform grain structure in the final product. The plates undergo multiple stages of rolling and annealing to refine the material’s mechanical properties. We utilize state-of-the-art machinery, including intermediate frequency sintering furnaces and vacuum arc melting furnaces, to maintain the highest quality standards. Finally, the products are subjected to rigorous testing to ensure they meet the specifications required by our clients.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a fully equipped production facility with advanced machinery designed for non-ferrous and refractory metal processing. Our factory spans over 10,000 square meters, housing specialized equipment such as vacuum annealing furnaces, CNC machines, and laser cutters. With a dedicated team of engineers and technicians, we ensure that every product leaving our facility meets international quality standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

-

Packaging Options

- Wooden crate packaging for large shipments

- Carton box packaging for smaller items

- Foam-filled packaging to prevent damage

- Waterproof and moisture-resistant packaging

- Custom packaging options available

- All packaging complies with international shipping standards

|

|

|

|

|

|

|

|

-

Logistics Options

- Sea freight for bulk orders

- Air freight for urgent deliveries

- Land transportation for regional shipments

- Multimodal transport solutions available

- Express courier services for small packages

Why Choose Us?

- Rich Experience: With over a decade of experience in the production and export of refractory metals, we have a deep understanding of the industry and the needs of our customers.

- Advanced Manufacturing: Our state-of-the-art facility ensures that we can produce high-quality molybdenum-lanthanum alloy plates with consistent performance.

- Global Reach: We export to multiple countries, including the United States, Germany, and South Korea, and have built strong relationships with international clients.

- Comprehensive Service: From material selection to final product delivery, we offer a full range of services, including custom manufacturing, technical support, and after-sales service.

- ISO 9001 Certified: Our commitment to quality is reflected in our ISO 9001 certification, ensuring that our processes meet the highest international standards.

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer custom manufacturing services to meet the specific needs of our clients. Whether you require unique dimensions, specialized treatments, or batch production, we are equipped to deliver tailored solutions. Our experienced team works closely with customers to ensure that every requirement is met with precision and efficiency.

Products Produced By Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

|

Frequently Asked Questions

-

What is the lead time for Mo-La alloy plates?

The lead time depends on the order quantity, but typically it ranges from 3 to 6 weeks. -

Can you provide custom sizes and thicknesses?

Yes, we offer custom sizes and thicknesses based on your specifications. -

Do you offer technical support for product applications?

Absolutely, our technical team is available to assist with any questions regarding the use of our products in your applications. -

How do you ensure the quality of your products?

All our products undergo rigorous testing, including mechanical and chemical analysis, to ensure they meet the required standards. -

What is your minimum order quantity?

The minimum order quantity varies depending on the product, but we offer flexibility to accommodate both large and small orders.

Contact Us

For more information on our Molybdenum-Lanthanum alloy plates or to place an order, please contact us at info@peakrisemetal.com. Our team is ready to assist with your inquiries and provide the best solutions for your needs. We welcome global buyers to collaborate with us and take advantage of our high-quality products and services.