customized sic heating elements

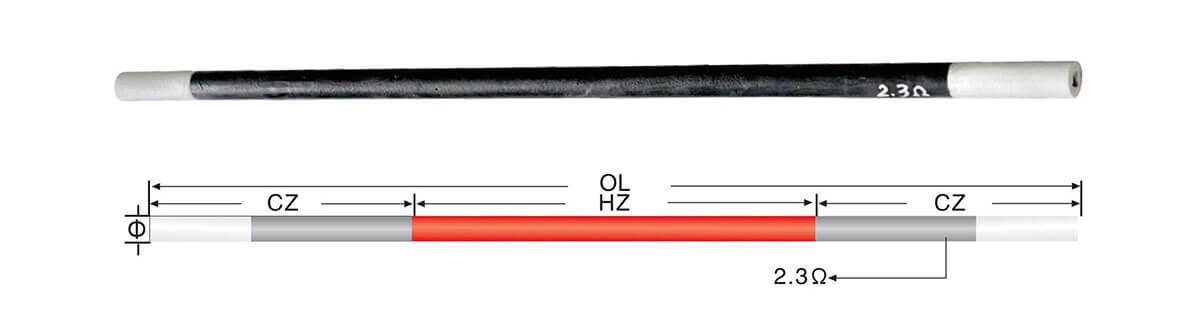

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Customized SiC Heating Elements for Global Industrial Applications

Product Introduction :

Silicon carbide (SiC) heating elements are widely regarded in various high-temperature industries for their exceptional performance and longevity. These elements are typically used in furnaces and kilns where extreme temperatures are required. As a leading supplier of customized SiC heating elements, Shaanxi Peakrise Metal Co., Ltd. is proud to offer a variety of solutions that meet the specific needs of global industrial markets. Our SiC heating elements are not only designed for efficiency but are also highly customizable, allowing us to tailor each element to specific client needs across industries such as metallurgy, ceramics, glass, and electronics.

Shaanxi Peakrise Metal Co., Ltd. has a long-standing reputation as a reliable supplier of high-performance non-ferrous metal products, including molybdenum, tungsten, tantalum, and titanium alloys. Since entering the international market in 2010, we have provided top-quality products, including customized SiC heating elements, to clients across Europe, the U.S., and Asia. Our dedication to innovation, coupled with over a decade of industry experience, makes us the go-to source for SiC heating elements that guarantee durability, efficiency, and optimal performance in high-temperature environments.

Product Parameters

|

|

|

|

Physical and Mechanical Properties

SiC heating elements are known for their unique combination of properties, making them ideal for high-temperature applications. With their high electrical resistivity and excellent thermal conductivity, these elements can maintain stable performance even under extreme conditions. The mechanical strength of our SiC heating elements ensures long service life, even in harsh environments. They also exhibit a high degree of hardness, which makes them resistant to wear and tear over time.

- Silicon carbon rods have high mechanical strength, with bending strength up to 100-120MPa.

- The high surface temperature can reach 1500 degrees.

- The infrared radiation rate is high, and the diameter of silicon carbon rods is 5-10 times that of ordinary nickel-chromium wires.

- Long service life, simple installation and maintenance.

- Silicon carbon rods have strong oxidation resistance, corrosion resistance, and excellent heat shock resistance.

|

|

|

Product Functions

- High-temperature stability: Our SiC heating elements can operate efficiently at temperatures as high as 1650°C, providing reliable heating for various industrial processes.

- Customizable resistance: These elements allow for adjustable electrical resistance based on the specific requirements of the application, offering flexibility and precise control.

- Energy efficiency: With superior thermal conductivity and surface load capabilities, our SiC heating elements ensure effective heat distribution, leading to energy savings in industrial operations.

- Durability: Made from premium-quality silicon carbide, these heating elements are built to withstand the stresses of high temperatures, corrosion, and oxidation, ensuring long service life.

- Versatile design options: Shaanxi Peakrise Metal Co., Ltd. provides customization for element shapes and configurations to meet the diverse needs of industries.

|

|

Product Applications

- Metallurgical Industry: SiC heating elements are essential for heat treatment, smelting, and metal hardening processes, where high-temperature stability is critical.

- Ceramics and Glass Manufacturing: These elements are perfect for kiln heating and glass tempering, where uniform heat distribution and temperature control are paramount.

- Electronics Industry: Used in furnaces for the production of semiconductors and other electronic components, our SiC elements ensure precision and high efficiency.

- Chemical Industry: SiC heating elements play a key role in chemical reactors and laboratory furnaces, where they are exposed to corrosive environments and require durability.

- Automotive and Aerospace: With their heat resistance, SiC elements are widely used in applications like exhaust testing, materials testing, and more.

|

|

Product Process and Production Flow :

Our SiC heating elements are manufactured through a meticulous process that ensures high quality and customization:

- Raw Material Preparation: The highest grade silicon carbide powder is processed and purified for use in the manufacturing process.

- Shaping and Molding: Elements are formed into their desired shapes (rod, U, W, or spiral) using advanced molding techniques.

- Sintering: The elements are sintered at high temperatures in vacuum furnaces to achieve the necessary physical and mechanical properties.

- Surface Treatment: After sintering, the elements undergo surface treatment to enhance their performance and resistance to oxidation.

- Quality Inspection: Each element undergoes rigorous testing to ensure it meets customer specifications, including resistance, density, and mechanical strength.

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates state-of-the-art facilities equipped with advanced production equipment such as vacuum arc melting furnaces, plasma cutters, and rolling mills. We pride ourselves on maintaining strict quality control standards at every stage of production. With nearly a decade of experience in the export market, we have established strong relationships with clients worldwide by delivering consistent, high-quality products.

|

|

Logistics and Packaging

- Packaging:

- Wooden crates for added protection during transportation.

- Foam-filled packaging to ensure stability and safety of delicate elements.

- Custom packaging available to meet the unique needs of our customers.

- Waterproof and moisture-proof packaging ensures product integrity.

- All packaging complies with international standards.

|

|

|

|

|

|

|

|

|

|

- Logistics:

- Sea freight for large, heavy shipments.

- Air freight for urgent or time-sensitive orders.

- Multimodal transport for complex supply chain solutions.

- Courier services for smaller, expedited orders.

Why Choose Us?

- Industry Expertise: Over a decade of experience in producing SiC heating elements and non-ferrous metal products for a global market.

- Custom Solutions: We offer full customization of SiC heating elements to meet the specific requirements of each client.

- Advanced Technology: Equipped with cutting-edge machinery, we ensure top-quality production at every step.

- Comprehensive Services: From R&D to production and quality control, we offer end-to-end solutions for our customers.

- Global Reach: Our products are recognized worldwide, and we have established long-term partnerships with clients across multiple industries.

FAQ

- What are the maximum operating temperatures for your SiC heating elements?

Our elements can operate up to 1650°C, depending on the specific model and application. - Do you offer customization for resistance and shape?

Yes, we provide full customization options for resistance, shape, and size to meet client requirements. - What industries use SiC heating elements?

SiC heating elements are commonly used in metallurgy, ceramics, glass, and electronics industries. - How long is the delivery time?

Standard products are usually delivered within 4-6 weeks, while custom orders may take longer based on specifications. - Do you provide OEM services?

Yes, we offer both OEM and ODM services to create customized solutions for our clients.

Contact Us

Looking for reliable, high-performance customized SiC heating elements? Contact Shaanxi Peakrise Metal Co., Ltd. today to discuss how we can meet your industrial heating needs. We welcome inquiries from global buyers—reach out to us at info@peakrisemetal.com. Let us help you find the perfect heating solution for your application!

YOU MAY LIKE

-

VIEW MOREsic heating elements

VIEW MOREsic heating elements -

VIEW MOREmosi2 heating elements

VIEW MOREmosi2 heating elements -

VIEW MOREGD type sic rod heating element

VIEW MOREGD type sic rod heating element -

VIEW MOREHigh density straight silicon carbide sic heating elements

VIEW MOREHigh density straight silicon carbide sic heating elements -

VIEW MORESingle thread silicon carbon rod heating element sic heater elements

VIEW MORESingle thread silicon carbon rod heating element sic heater elements -

VIEW MORELS shape (double helix) silicon carbide heating element

VIEW MORELS shape (double helix) silicon carbide heating element -

VIEW MOREDouble threaded silicon carbon rod heating element

VIEW MOREDouble threaded silicon carbon rod heating element -

VIEW MOREu shape sic heating element Silicon Carbon rod

VIEW MOREu shape sic heating element Silicon Carbon rod